Local News

GTL Americas unveils steps for clean energy transition

Pine Bluff, Arkansas – GTL Americas is on the verge of making history with its groundbreaking gas-to-liquid (GTL) facility in Jefferson County, near the National Center for Toxicological Research. This project, hailed as the largest industrial initiative in Arkansas, represents a significant leap in the field of clean energy.

Leon Codron, president of GTL Americas, recently spoke to the Pine Bluff Small Business Association about the progress of America’s first GTL facility. He detailed the front-end engineering and design (FEED) phase, which began with partnerships with Hyundai ENG America and S&B Engineers and Constructors Ltd. in September. This phase is expected to take 14 to 16 months, aligning with the initial 18- to 24-month projection.

The mission of GTL Americas is ambitious: to produce ultra-clean, low-emission, biodegradable fuels for transportation. Codron emphasized the unique quality of their diesel, comparing its color and purity to water. This diesel, with a high cetane rating of 75, promises superior performance compared to traditional diesel, burning cooler, lasting longer, and requiring less maintenance.

The FEED phase is a critical step in the project’s development, laying the groundwork for the engineering, procurement, and construction (EPC) phase, slated to begin in late 2025. The facility’s commissioning phase is anticipated to start towards the end of the EPC phase in 2028, with commercial operations expected by 2029.

Codron outlined the construction plan, which includes building access roads, preparing the site, constructing infrastructure, and setting up the main office. Notably, financing is on track, with debt financing up to 70% of the project’s needs being “spoken for”. A consortium of international banks, including ING Bank, Intesa Sanpaolo, KFW, and MUFG, has been identified to underwrite the majority of the debt requirements.

A key aspect of GTL technology, as explained by Codron, is its differentiation from the liquefied natural gas (LNG) industry. While LNG involves freezing and re-warming natural gas, GTL technology converts gas into a solid state. This innovation is particularly relevant given the abundance of natural gas in the United States due to advanced fracking technologies.

Addressing environmental concerns, Codron discussed the carbon dioxide emissions associated with the facility. He emphasized GTL Americas’ commitment to meeting Scope 1 and Scope 2 standards for direct greenhouse gas emissions, ensuring both onsite and electricity-related emissions are offset. Additionally, he mentioned the possibility of storing the carbon dioxide produced by the facility in an aquifer, highlighting that the GTL facility’s CO2 footprint is 25% less than a traditional refinery.

GTL Americas’ project is not only a technical marvel but also a beacon of hope in the fight against climate change. By producing cleaner fuel and addressing carbon emissions responsibly, the facility sets a new standard for industrial projects worldwide. As the project progresses towards its completion, it stands as a testament to the potential of innovative technologies in reshaping our energy landscape and contributing to a more sustainable future.

-

Covid-191 year ago

Covid-191 year agoIngesting an excessive amount of vitamin D may result in serious health consequences

-

Arkansas1 year ago

Arkansas1 year agoHuman remains discovered near a popular Arkansas hiking trail believed to be person missing since 2021

-

Arkansas1 year ago

Arkansas1 year agoDriver in fatal single-vehicle accident in White County identified by authorities

-

Local News1 year ago

Local News1 year agoA Sylvan Hills High School student’s painting receives considerable acclaim

-

Arkansas3 years ago

Arkansas3 years agoArkansas Trying to Close Out Regular Season With Series Win Over Florida

-

Arkansas3 years ago

Arkansas3 years agoMickelson changes his mind, accepts exemption to US Open

-

Arkansas2 years ago

Arkansas2 years agoDue to the COVID Pandemic, Arkansas’ math and reading test scores have decreased

-

Covid-191 year ago

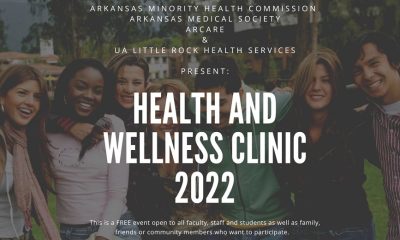

Covid-191 year agoHealth and Wellness Clinic will be held on November 3 at UA Little Rock

Leave a Reply